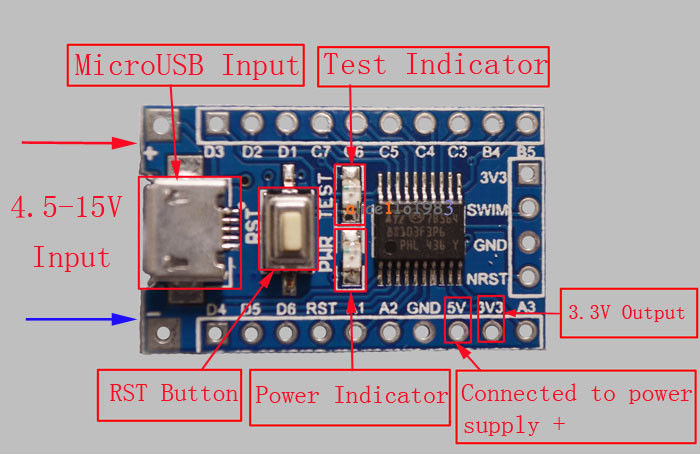

Generic STM8S103 breakout board

These simple breakout boards are available on aliexpress for well under one Dollar (I got mine for 67 cent each, including shipping from China). These boards are my main development platform.

They are very similar to the ESP14 Wifi-boards and most programs will work fine on those chinese gems as well.

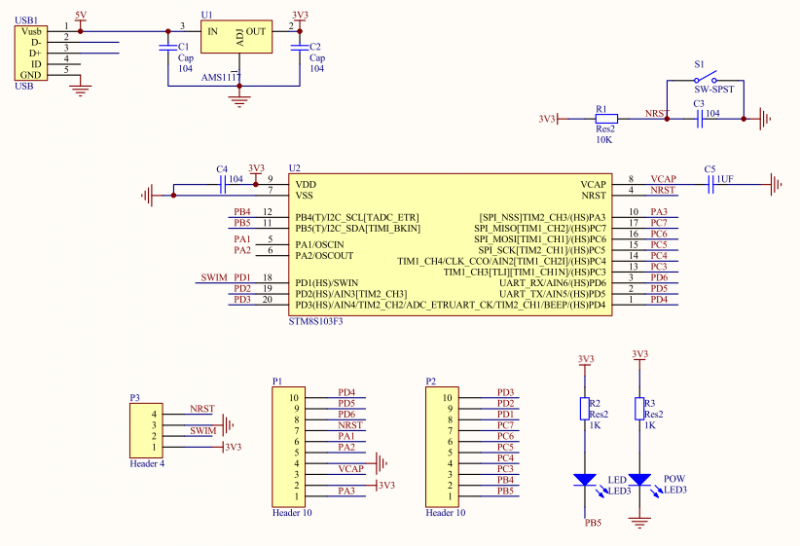

The STM8S103 breakout boards are build around a CPU STM8S103F3P6 with 16MHz internal oscillator, 8kB flash, 1kB RAM, and 640 byte EEPROM. The CPU includes a UART, SPI, I2C, PWM, 10 bit ADC, 3 timer, and up to 14 I/O pins - quite similar to an Atmel ATmega8.

One (red) LED is connected to GPIO PB5 (CPU pin 11). This LED is low active. Please keep in mind that this is one of the I2C signals and using the LED blocks the I2C bus. The push button is for reset. The CPU runs on 3.3V, a linear regulator is integrated on the board. The micro USB connector is only for (5V) power supply, the data lines are not connected.

All CPU pins are easily accessible on (optional) pin headers (pitch 2.54mm, perfect for breadboards).

Unlocking a write protected MCU

My breakout boards came preprogrammed with a blink program and with active write protection bits. For unlocking before first use using the command line:

stm8flash -cstlinkv2 -pstm8s103?3 -u

The same can be done from the Arduino IDE by clicking on Tools->Burn Bootloader after selecting an STM8 based board and choosing the correct programmer type (ST-Link V2). The name of this menu entry is not self-explanatory, but I couldn’t find any way to change it or to add another entry with a better name. (If you know how, please open an issue)

The required binary for stm8flash is included in the download of the

automatic install. On Windows systems it can be found in the directory

AppData\Local\Arduino15\packages\sduino\tools\STM8Tools\2019.02.05\win.

A GUI alternative is the STVP tool by ST, but this involves installing another software package (see issue#85).

Connection to the flash tool

I am using the ST-Link V2 compatible flash tool in the green plastic housing. The one in the metal housing uses a different pinout.

Connection to the flashtool:

| Signal name | P3 on CPU board | Green flash tool | Metal flash tool |

|---|---|---|---|

| 3V3 | 1 | 2 | 7 |

| SWIM | 2 | 5 | 5 |

| GND | 3 | 7 | 3 |

| NRST | 4 | 9 | 1 |

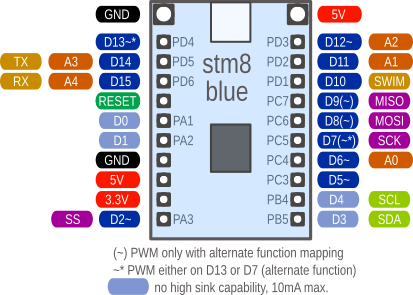

Pin number mappings

The Arduino environment uses its own pin numbering scheme independent from the physical CPU pin numbers. Many Arduino sketches and libraries contain hard-coded assumptions about the number of pins with special functions. Ideally, all these numbers would be the same and all programs could be compiled without changes.

Here I discuss some possible pin mapping schemes and check how close we could get the the ideal mapping. Unfortunatly, it turns out that a perfect mapping is not possible.

In the end I chose a simple geometric numbering for the square UFQFPN20 package starting with port pin PA1 and counting up from 0. This results in this mapping:

| sduino pin | STM8S103 CPU port pin |

|---|---|

| 0-2 | PA1-PA3 (PA1 and PA2 only weak output drivers) |

| 3-4 | PB5-PB4 (reverse order) |

| 5-9 | PC3-PC7 |

| 10-15 | PD1-PD6 |

- serial: 14,15

- SPI: 2,7,8,9

- I2C: 3,4 (true open drain. can’t drive a high signal without an external pull-up resistor)

- Analog: 6,11,12,14,15

- PWM: 2,5,6,12 plus either only 13 or 7-9 but not 13 (via alternate mapping)

pros of this approach:

- Easy and logical for use on a breadboard

- Very clear and logical port pin ordering

- TX and RX would be the rarely used analog pin numbers A3/A4 at the end of the analog pin number list

- At least the analog pins are in data sheet order

cons of this approach:

- Analog pins are still scattered around

- All functions use totally different pin numbers than Arduino

I am still not really happy with this mapping. Instead of simplifing things

it only adds another layer of abstraction and confusion. To avoid this I

added definitions for the regular CPU pin names like PA1 and PD2. In the

end, this notation seems to be a lot easier to me. I am open for suggestions

for a better pin number mapping.

The chosen pin mapping for the STM8S103 (possible alternate function in paratheses):

| Phys. STM8 pin | Name | Functions | Geometrical mapping | special funcion |

|---|---|---|---|---|

| 1 | PD4 | UART_CLK/T2-1/beep | 13 | PWM |

| 2 | PD5 | TX/Ain5 | 14 | Analog A3 |

| 3 | PD6 | RX/Ain6 | 15 | Analog A4 |

| 5 | PA1 | (OscIn, no HS) | 0 | |

| 6 | PA2 | (OscIn, no HS) | 1 | |

| 10 | PA3 | SS/T2-3 | 2 | PWM |

| 11 | PB5 | SDA LED | 3 | |

| 12 | PB4 | SCL | 4 | |

| 13 | PC3 | T1-3/[T1-n1] | 5 | PWM, (n~) |

| 14 | PC4 | T1-4/Ain2/[T1-n2] | 6 | PWM, Analog A0, (n~) |

| 15 | PC5 | SCK/[T2-1] | 7 | (~) |

| 16 | PC6 | MOSI/[T1-1] | 8 | (~) |

| 17 | PC7 | MISO/[T1-2] | 9 | (~) |

| 18 | PD1 | (SWIM) | 10 | |

| 19 | PD2 | Ain3/[T2-3] | 11 | Analog A1, (~~) |

| 20 | PD3 | Ain4/T2-2 | 12 | PWM, Analog A2 |

Special pins

The pins D3/D4 (SDA/SCL, PB5/PB4) are different from the others as they are true open drain pins. That means, they only can drive the output low or open. To drive it high, they require an external pull-up resistor. This is the reason why the LED on this breakout board is connected between +3.3V and the pins and not between the pin and GND as usual. This way it is possible to drive the LED by writing a zero to the output register.

D5/D6 (PA1/PA2, OscIn/OscOut) are weaker than the other pins. Try avoiding these pins for LEDs and other higher current applications.